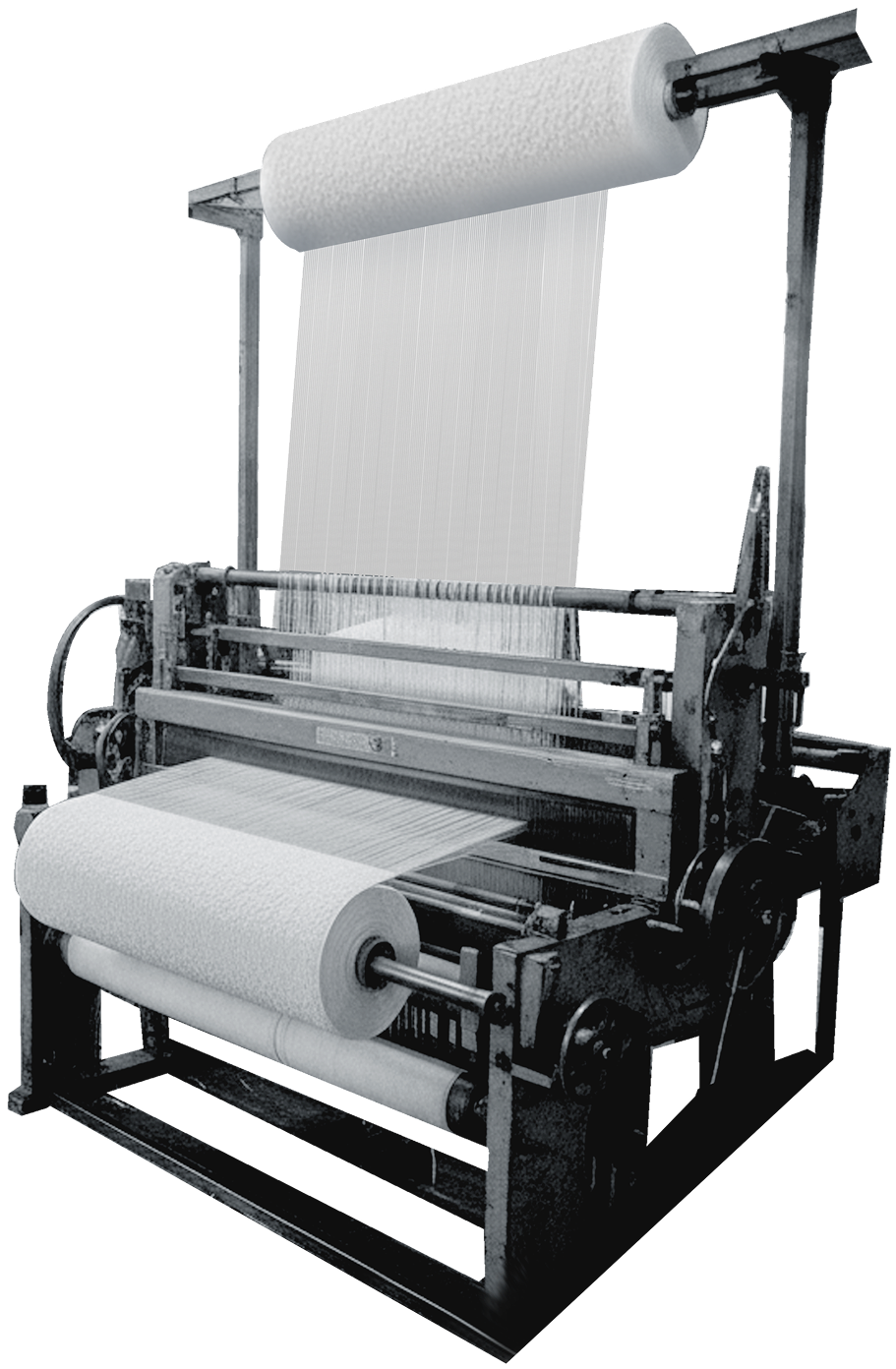

We began our journey in 1982, in the heart of Karachi, Sindh, Pakistan. Founded as a family-run business, we started with a modest setup of just two looms. This marked the beginning of a vision to establish a leading textile manufacturer, leveraging the strategic location of Karachi, a vital port city, to facilitate future growth and international trade.

Recognizing the growing demand for quality terry towels, We expanded its operations in 1986 by establishing a second production unit in the Sindh Industrial Trading Estate (SITE) area of Karachi.

Continuing its growth trajectory, We launched a significant new production unit in the Korangi industrial area of Karachi in 2002. This expansion broadened the company’s manufacturing footprint, allowing for increased production volume and diversification of product lines. It showcased the company’s ability to capitalize on Karachi’s industrial infrastructure.

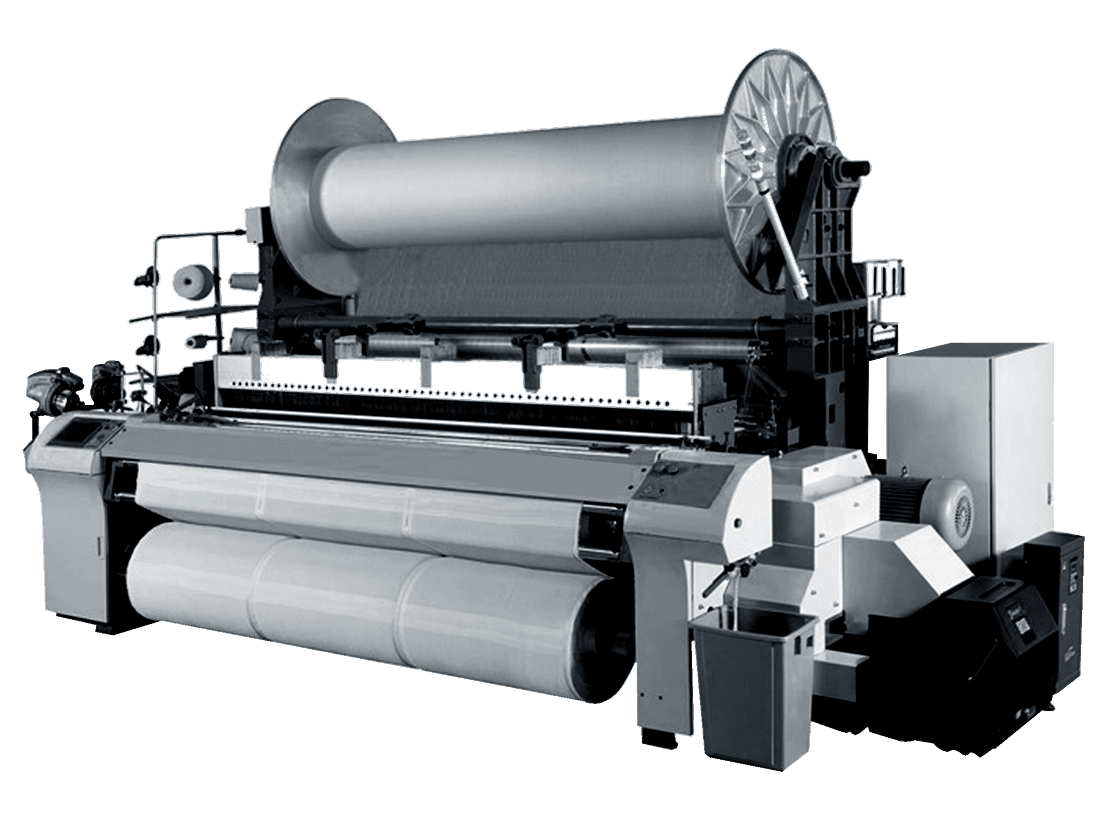

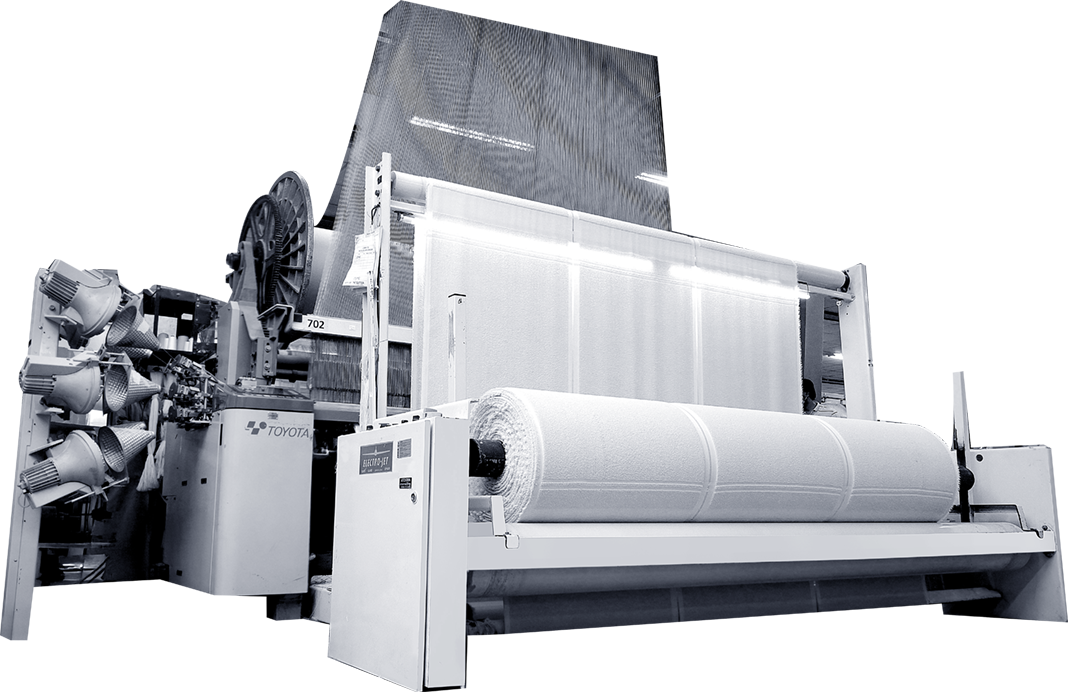

In 2004, We embraced technological advancement by introducing its first batch of Shuttleless looms. This modernization significantly enhanced production efficiency and product quality, reflecting the company’s commitment to staying at the forefront of textile manufacturing technology. This was a large step in modernization of their production process

Demonstrating its dedication to quality and operational excellence, We achieved ISO 9001 certification in 2004. This certification validated the company’s established quality management systems, assuring customers of consistent and high-quality products. This was an important step in gaining international trust.

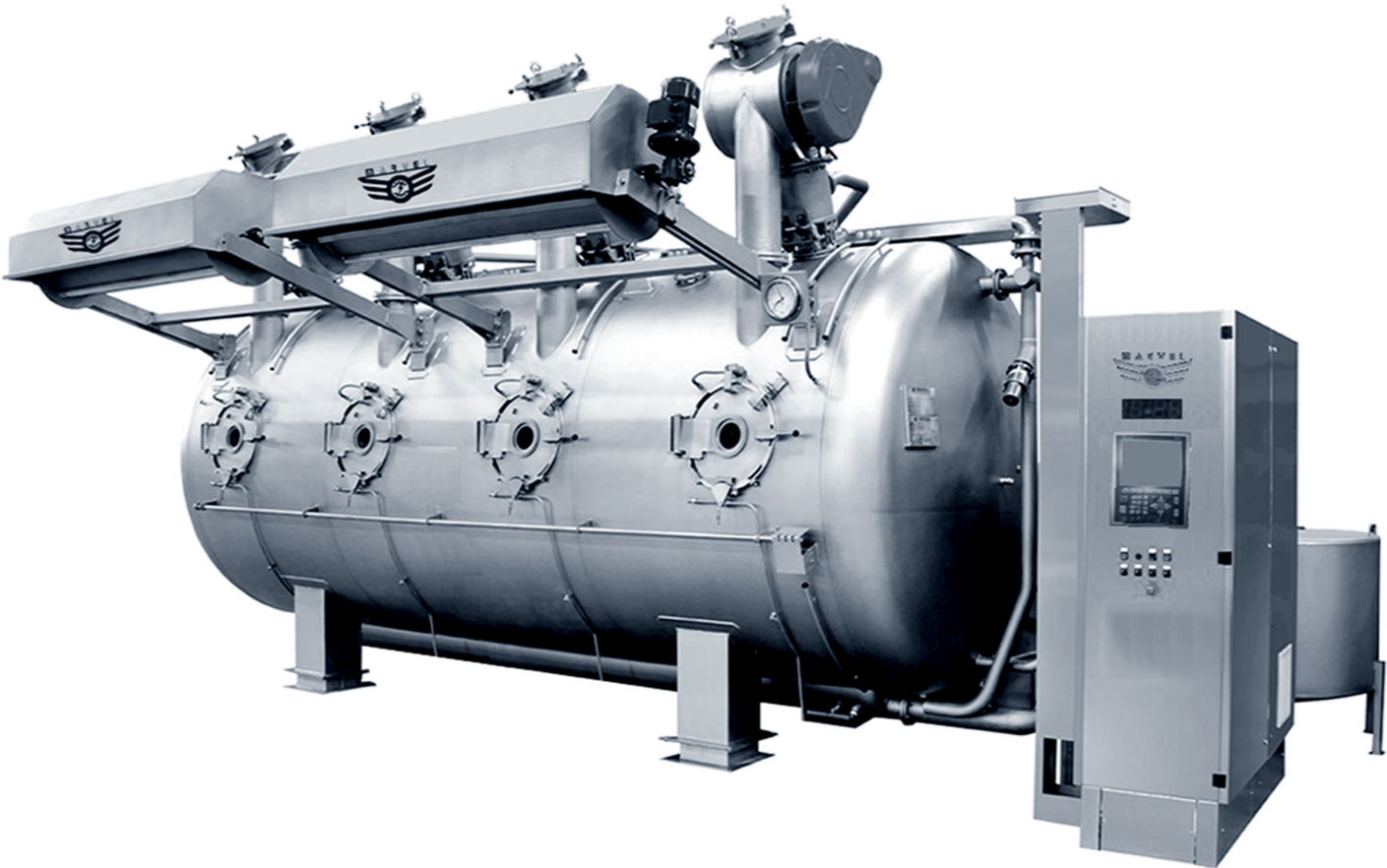

To further enhance product quality and meet evolving customer demands, United Towel Exporters achieved state-of-the-art dyeing capabilities in 2010. This investment in advanced dyeing technology allowed for greater control over color consistency and durability, strengthening the company’s position as a premium textile manufacturer.

United Towel Exporters demonstrated its commitment to ethical and responsible business practices by obtaining BSCI, SEDEX, CTPAT, and REACH certifications in 2011. These certifications affirmed the company’s adherence to social compliance, supply chain security, and environmental regulations, reflecting its dedication to global standards.

In 2013, We achieved OEKO-TEX Standard 100 certification, ensuring that its products are free from harmful substances. This certification reinforced the company’s commitment to producing safe and environmentally friendly textiles, meeting the stringent requirements of international markets.

United Towel Exporters transitioned to a partnership firm in 2014. This structural change likely aimed to optimize operational efficiency and strategic decision-making, positioning the company for continued growth and adaptability within the dynamic textile industry.

In 2015, the company started its Air jet Division. This further modernized the weaving process, and allowed for higher production speeds, and higher quality finished goods.

We have achieved BCI certification in 2016, demonstrating a commitment to sustainable cotton sourcing. This certification supports environmentally and socially responsible cotton farming practices, aligning with global efforts to promote sustainable agriculture.

The inauguration of a new production unit in Landhi, Karachi, in 2018 marked another significant expansion for UTE. This expansion increased production capacity and further solidified the company’s presence within Karachi’s industrial landscape.

In 2020, We have achieved MADE IN GREEN, GOTS, and GRS certifications, highlighting its dedication to sustainable and environmentally responsible textile production. These certifications assure customers that the company’s products are produced in a socially and environmentally responsible manner.

The inauguration of a new dyeing and finishing department in 2022 enhanced UTE vertical integration. This investment allowed for greater control over the entire production process, ensuring consistent quality and meeting specific customer requirements.

In 2023, We obtained further certifications, including SCAN, Egyptian Cotton, OEKO-TEX Organic, and EU Eco Label. These certifications demonstrate a commitment to premium materials, organic production, and environmental sustainability, catering to discerning customers worldwide.

The inauguration of an Effluent Treatment Plant (ETP) in 2023 underscored UTE’ commitment to environmental responsibility. This significant investment in wastewater treatment technology minimized the company’s environmental impact, aligning with sustainable manufacturing practices.

The inauguration of a new office in 2024 likely signifies continued growth and expansion of administrative and operational capabilities. This new office space will allow for better organization and better communication within the company.

All Right Receive UTE WEBSITE

Copyright © 2025. All rights reserved.