SDL top load washing machine.Wascator front load washing machine.Milnor commercial washer Whirlpool tumble dryer Electolux tumble dryer Milnor commercial dryer Gester crock meter Roaches perspirometer Gyrowash color fastness tester James heal GSM cutter Mettler Toledo pH meter.

We are dedicated to delivering products of the highest quality. To ensure this, our state-of-the-art laboratory conducts a comprehensive range of tests on our fabrics:

At the heart of our design process lies a suite of industry-standard tools and software. Adobe Photoshop, Illustrator, and CorelDRAW are our primary tools for creating stunning and innovative designs.

At UTE, warping is a foundational step in our manufacturing process, setting the stage for the exceptional quality our clients expect. Warping involves the careful alignment and winding of yarns onto a beam, preparing them for weaving with precision and consistency. This crucial process ensures that every towel we produce has the strength, durability, and visual appeal that meets our high standards. Every stage of our warping process is subject to rigorous quality checks to ensure consistency and minimize waste. Our team follows strict protocols to monitor yarn tension, alignment, and winding speed, ensuring the warp is perfect before it heads to the weaving stage.

Our weaving process prioritizes exceptional quality and sustainability. We use a variety of premium yarns, including 100% cotton, polypropylene, polyester, BCI-certified, GOTS-certified organic, and GRS-certified recycled yarns.

Our processing department utilizes advanced techniques such as Exhaust and Semi-Continuous Dyeing for terry, towel, and knit fabrics.

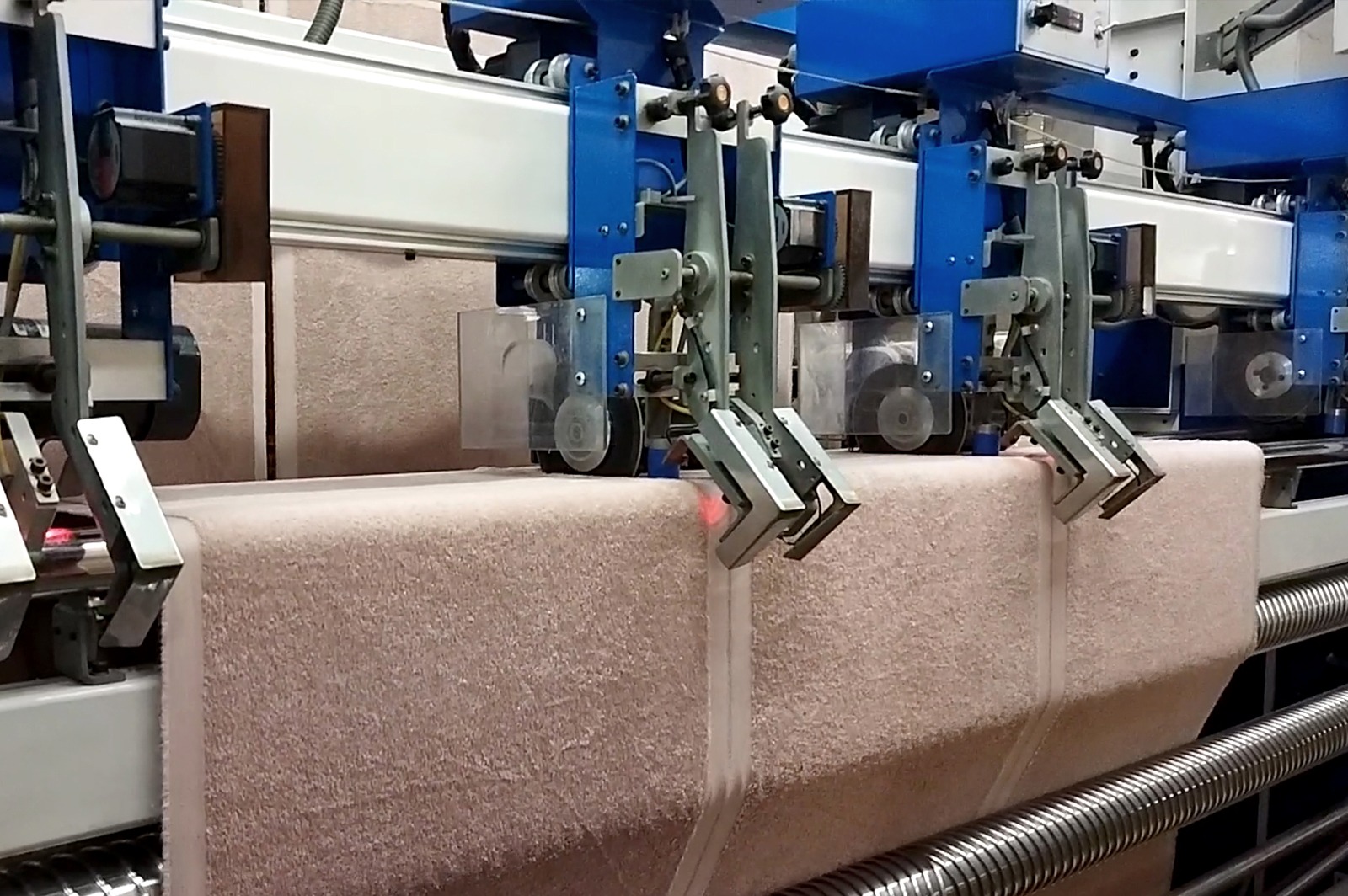

Keeping in line with the ever-changing world, we have installed upgraded, fast, and efficient cutting and sewing machines. Moreover, our devoted specialists are assisted with Bando Auto Long Slitting Machines, Bando Auto Long Hemming Machines, Juki Manual Long Hemming Machines, Auto Trimmer Side Hemming Machines, Safety Overlock Machines, which ensures superior quality of hemming and stitching.

Our stitching facilities feature a wide array of state-of-the-art machines, including single-needle, double-needle, overlock, safety, and flatlock machines.

We utilize a variety of embroidery techniques to bring your vision to life. From classic styles like Tatami, cross, satin running, and zig-zag stitching to modern capabilities with computerized embroidery machines, we offer a comprehensive range of options to enhance your towels.

Our spacious storage facility helps us to organize and optimize the distribution of products securely and constructively. Our well-managed warehouse assists in reducing errors or damage during handling. Moreover, it helps us to acquire greater customer satisfaction by allowing deliveries to be punctual and managing lead time efficiently.

All Right Receive UTE WEBSITE

Copyright © 2025. All rights reserved.